Disposable Syringe Manufacturing License

The CDSCO (Central Drugs Standard Control Organization) serves as the regulatory authority overseeing pharmaceuticals and medical devices in India. Manufacturers of medical devices, such as disposable syringes, must obtain a manufacturing license from the CDSCO to legally produce these items within the country.

Securing a CDSCO manufacturing license is a compulsory regulatory step for the production of disposable syringes in India. This license ensures that manufacturers adhere to required quality standards, safety regulations, and guidelines mandated by the CDSCO. The licensing process entails a comprehensive assessment of the manufacturing facility, procedures, quality control protocols, and adherence to Good Manufacturing Practices (GMP) as outlined by regulatory authorities.

Needle and Disposable Syringe Manufacturing Line Process Guidance

Many manufacturers struggle with the initiation process, they do want to set up the plant and move forward but they are behind due to adequate knowledge. We can resolve their doubts about disposable syringes by guiding the plant layout design, clean room design, product feasibility, and regulatory aspects. Disposable devices are notified devices and they need the CDSCO manufacturing license. As per the latest notification of CDSCO, the manufacturer who fails to register their device may face action against them. To avoid this action you can speed up the CDSCO registration process with our team.

With extensive technical experience, Operon Strategist is the best consulting company for syringe manufacturers in India. Provides the best project management turnkey solutions for medical device manufacturing.

Looking for Disposable Syringe Manufacturing Process Consultant?

Let’s have word about your project

Disposable Syringe Manufacturing Process

A disposable syringe is a basic responding siphon comprising a plunger (however, in present-day syringes, it is a cylinder) that fits firmly inside a round and hollow cylinder called a barrel. For syringe manufacturing, the plunger can be directly pulled and pushed along within the cylinder, enabling the syringe to take in and oust fluid or gas through a release hole at the front (open) part of the cylinder.

The open part of the bargain might be fitted with a hypodermic needle, a spout, or tubing to coordinate the stream into and out of the barrel. Syringes are as often as possible utilized in clinical medication to control infusions, imbue intravenous treatment into the circulatory system, apply mixes, for example, paste or oil, and draw/measure fluids.

Firstly all the disposable syringes & needle production line is manufactured with the use of Polypropylene. You have to decide on which type of sizes you want to make. The normal standard charges are 1ml, 2ml, 5ml and 10ml. because of health awareness and health consciousness, you can get a lot of profit from the needle and disposable syringe manufacturing business.

Initially, glass dominated the production lines for syringes and needles. However, disposable syringes are swiftly gaining traction due to their convenience, sanitary conditions, and cost-effectiveness. The global emergence of AIDS and other fatal diseases has underscored the importance of avoiding syringe reuse, leading to a substantial surge in demand for disposable alternatives.

For More Details About Disposable Syringes Manufacturing

Machinery Used for Needles and Disposable Syringe Manufacturing:

- Sterilization Plant

- Blister Packaging machinen

- Automatic packaging machine

- Scrap Guiding machine

- Zigma injection molding machine

- Weighing scale

- Water Pump

- Air Compressor

- Chilling Plant

- Testing Equipment

- Electrical Fittings & Socket

- Set of molds for barrels

- Set of molds for syringes body 16 cavities for barrel & 16 cavity for plungers.

Raw Materials Used for Needles and Disposable Syringe Manufacturing and Other Requirements

There are generally two types of raw materials, required to manufacture syringes. The first thing is polypropylene and the other is the needle. Land requirement is generally decided according to your business size.

Raw materials which are used in this business

- Polypropylene

- Ethylene Oxide

- Packing paper

- Rubber gaskets

- Needles

- Printing Ink

Required Manpower:

If you are planning to start an average size business of syringe manufacturing things you may need for your plant

- Skilled workers/Unskilled workers

- Supervisors

- Security

- Account assistant

- Marketing executive

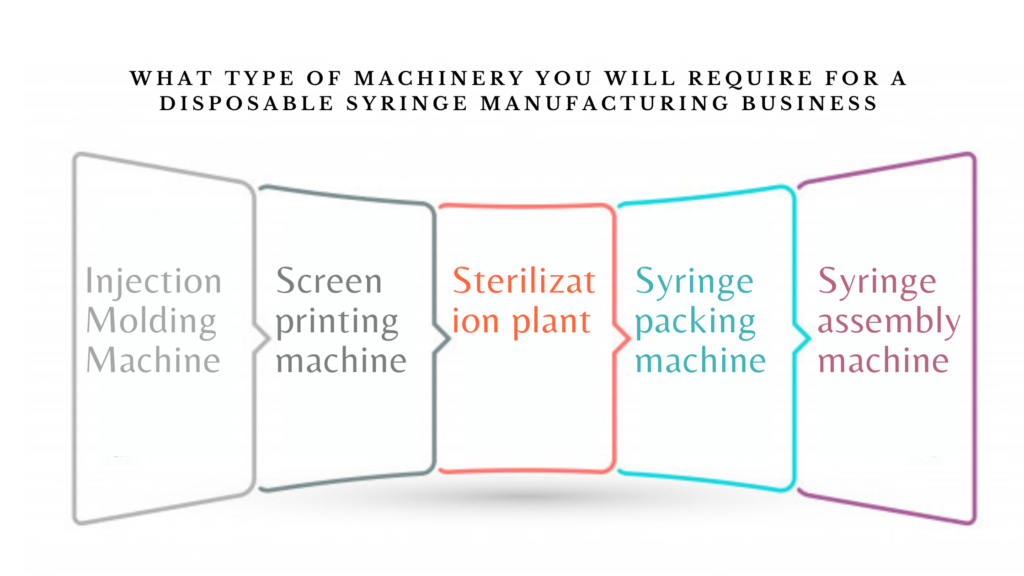

What Type of Machinery will Require for a Disposable Syringe Manufacturing Business?

For factory design or unite design of disposable syringe you will require following machinery :

- Injection Molding Machine

An injection molding machine also known as an injection press is a kind of machine used for manufacturing plastic products with the Injection molding production. Types of injection molding machines,

Mechanical

This type of machine is used to toggle the system for building up the tonnage on the side of the machine, that does not open due to injection pressure.

Hydraulic

These machines are not that nearly precise, and are the predominant type in most of the world.

Electric

The electric press also known as electric machine technology, reduces the cost by cutting the consumption of energy. Electric press is said to be quieter, faster, and have the highest accuracy.

Also, Read – Why follow safe injection syringes & standards?

- Screen printing machine

After the completion of the first step, the next thing is to print the injections appropriate to their standard level marking. You have to make sure about the alternative machine for manufacturing companies for price variation.

- Sterilization plant

For the sterilization process, they have to use ethylene oxide. Ethylene oxide (ETO) is known as the gas used for low-temperature sterilization. It is generally used to sterilize instruments or devices and all those products that have to be sterilized but cannot stand high temperatures.

- Syringe packing machine

The syringe packing machine is used for the automatic syringe mass packing. For this, you have to check all types of machine sizes and prices at every different industrial machine store.

- Syringe assembly machine

For the syringe Assembly machine, a hopper and a bowl feed the syringe plungers with the help of an inline track to a dead track where they are picked and placed 2 up into a double nest onto a 24 position on an indexed dial plate. In the Disposable Syringe assembly machine hopper and bowl feed needle-in-hubs and 2 up places needles on barrels.

Also read, Top 5 Syringe Making Machine Manufacturers

You can always choose Operon Strategist medical device consultancy which provides cost-effective regulatory services for timely results. Read the blog here about How to Manufacture Disposable Syringe. We also provide CE certification consultation in Saudi Arabia, the USA, and Egypt.

FAQs

Is syringe manufacturing profitable?

Manufacturers of syringes and needles - two basic items in any medical setup - enjoy a whopping trade margin ranging from 250-1,250%, according to a new analysis by the National Pharmaceutical Pricing Authority (NPPA).

What are disposable syringes made of?

Disposable Syringe Body and plunger are made from polypropylene, seal on plunger is made from polyisoprene (rubber).

How is a syringe produced?

A three-part syringe contains a plastic plunger/piston with a rubber tip to create a seal between the piston and the barrel, where a two-part syringe is manufactured to create a perfect fit between the plastic plunger and the barrel to create the seal without the need for a separate synthetic rubber piston.

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/